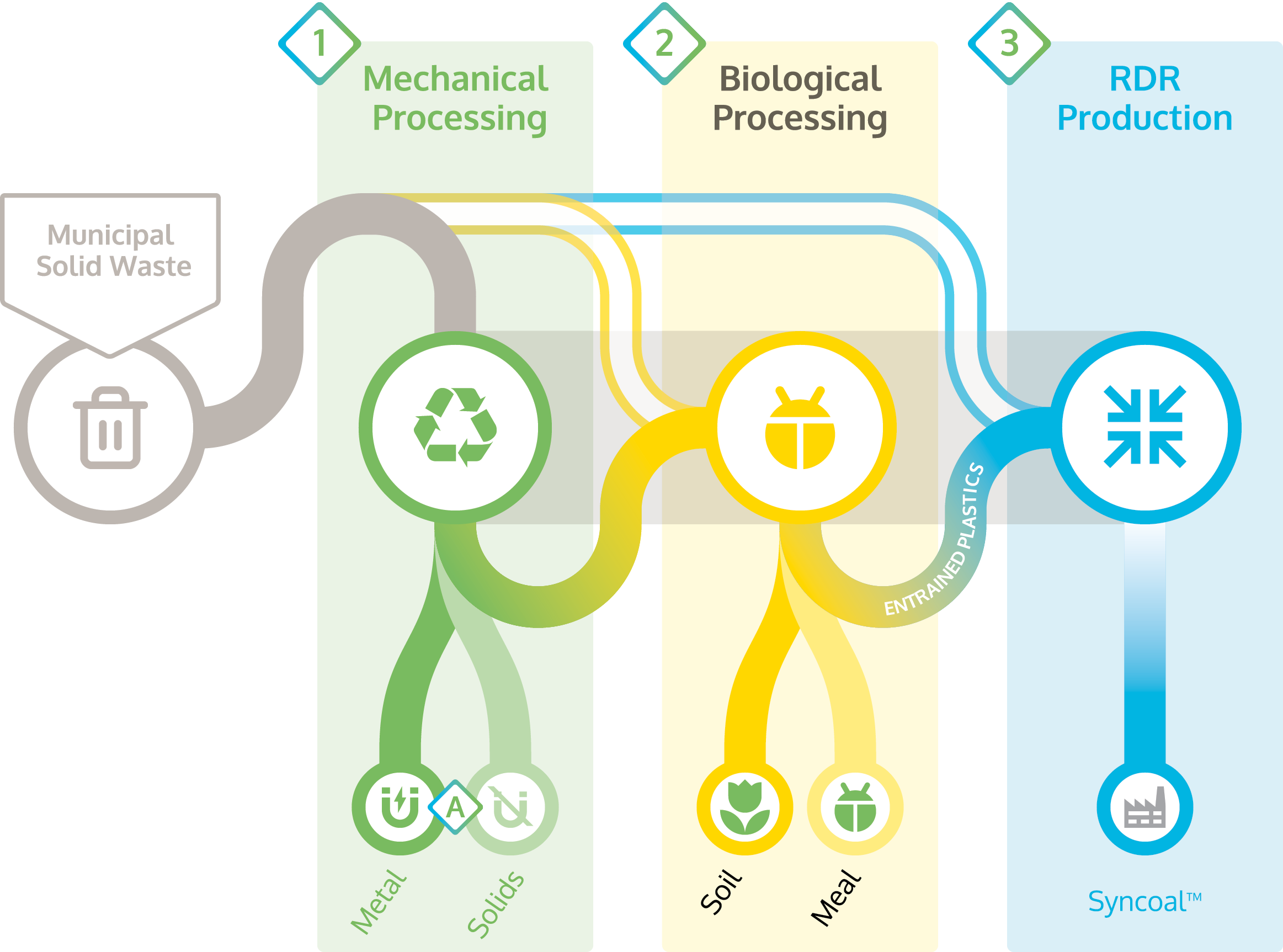

The first complete waste-to-resource recovery system

Entoq’s innovative technology transforms municipal solid waste (MSW) into valuable resources, including high-grade insect meal, high-nutrient fertilizer, and Syncoal™, an industrial reductant that can replace coking coal. Our process combines biological and mechanical processes to recover, re-form, and re-purpose MSW elements, significantly reducing the amount of waste going into landfills.

The Entoq Process

The Entoq Process consists of a continuous series of biological and mechanical processes which converts MSW into marketable commodities: a High grade insect meal, High nutrient fertilizer, and SynCoal™, an innovative industrial reductant which can replace coking coal. The process consists of conventional methods of waste preparation and segregation augmented by innovative technologies that recover, re-form and re-purpose the MSW elements, significantly reducing the amount of mixed solid waste going into landfill. Entoq’s comprehensive approach is the strength of our system.

Entoq Digester

Adaptable to all MSW containing both organic and inorganic content. Utilizes BSF larvae to recover nutrients and convert them into bio-products: agriculture grade wastes convert to animal feeds and fertilizer; industrial grade wastes convert to bio-energy products (bio-diesel and Sustainable Aviation Fuel) and pharmaceuticals. Provides an effective bio-cleaning system that requires low energy and is environmentally viable (uses no water).

Syncoal Production

Total process recovery is optimized by manufacturing Syncoal™ from the residual waste containing plastics and undigested organics. Syncoal™ is a commercially and environmentally viable alternative to natural coal and blended metallurgical coke. The Syncoal™ densification process provides an efficient means for harvesting carbon and hydrogen for separate recovery. It does not require any chemicals, is energy efficient and can process any form or structure of waste plastic and residual organic material.

Landfill diversion

Enables high landfill diversion rates of >75% by recovering, re- forming and re-purposing MSW into alternative sustainable commodities. Extends the useful life of assets (land and air). Provides a resource recovery circular model, meeting social, environmental and commercial needs. Completely prevents methane emissions in landfill and requires significantly less land area compared to conventional waste processing facilities.

NetZero Outcomes

No methane generation. Carbon capture in bio-products. Carbon and hydrogen recovery in Syncoal™. Low energy and carbon footprint manufacturing process. Low carbon footprint for all aspects of the process. Potential generation of carbon credits.

A continuous system

Entoq’s MSW treatment process is continuous and covers both organic and inorganic wastes.